|

| June 23, 2015 | Volume 11 Issue 24 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Cobbled-together Frankenphone improves Air Force air-to-ground communications

By Airman 1st Class Christian Clausen, 432nd Wing/432nd Air Expeditionary Wing

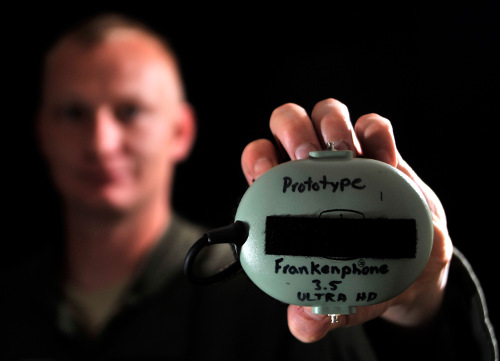

Staff Sgt. Marion, a 42nd Attack Squadron sensor operator, displays his invention, the "Frankenphone 3.5 Ultra High Definition," March 24, 2015, at Creech Air Force Base, NV. The Frankenphone gets its name because of the way it's patched together from decommissioned pieces of equipment. It's a simple design, but the Frankenphone improves air-to-ground communications by putting the aircrew and joint terminal attack controllers on a party line. [U.S. Air Force photo/Airman 1st Class Christian Clausen]

In a crowded room of remotely piloted aircraft (RPAs) sensor operators, it would be easy to overlook him, yet his accomplishments scream for attention. His peers have labeled him a "jack-of-all-trades," and after getting past his quiet first impression, it's easy to see why.

For Staff Sgt. Marion, a 42nd Attack Squadron sensor operator, it all began before he even considered wearing the uniform. When he was a child, at the age of 13, he began welding. He started building go-karts first, and at age 17 he started his first official welding job building race cars. At age 20, he began building computers and working with circuitry, until he decided to enlist in the Air Force at 23.

"I just married my wife, and we were planning on starting a family; the job I had paid well, but the military was stable," Marion said. "And I wanted to serve my country as well."

Although a skilled welder, this wasn't what earned him his label among his peers. It was the combination of hands-on abilities that have taken him years to acquire through woodworking, circuitry, landscaping, sheetrock work, and house rewiring.

"Anything I've set my mind to, I can do. I just do some research," Marion said. "My wife's always surprised by the stuff I can do and build."

Although he's gathered skills off duty, his abilities aren't bound to just life outside the military. Marion contributed his talents to furthering the Air Force mission when he repurposed materials in two different Air Force specialty codes.

"I was in cable antenna maintenance prior to being a sensor operator, and I took equipment in its original form. Without needing specialized tools to get the job done, I was able to repurpose it," Marion said.

Most recently, he distinguished himself by fashioning a device that helped increase communications quality, and reduced piloting complications while flying RPAs.

Now, two years later and on its third variation, the pocket-size contraption has been dubbed "Frankenphone 3.5 Ultra High Definition," due to its crude manifestation. It doesn't look like it is much of anything, but it's incredibly simple and a highly effective way to complete the mission.

Like its name suggests, the phone is patched together from pieces of equipment that are heading for the scrap pile.

"It's made of a phone receiver that has been retired, and an old headset which either had microphones or speakers quit working," Marion said.

Staff Sgt. Marion was recognized by Air Force leadership for constructing a device that simplifies life in the ground control station while flying remotely piloted aircraft, allowing operators to seamlessly execute the mission and save lives. [U.S. Air Force photo/Airman 1st Class Christian Clausen]

Faced with budget constraints, RPA crews were operating with outdated communication systems while still having to ensure accurate mission planning and execution with ground forces. While the design is simple, what the Frankenphone does for the Air Force is nothing short of incredible, according to Gen. Herbert J. Carlisle, the commander of Air Combat Command.

"It's amazing," Carlisle said. "It's a classic case of innovation. Ultimately, we needed to build a piece of equipment that would allow us to talk through a phone while we're still on the radio and (flying the aircraft). Frankenphone is the kind of innovation (the Air Force) needs."

RPA pilots were presented with a challenging method of relaying messages with joint terminal attack controllers and to the rest of the aircrew.

When a JTAC called into the phone line, a pilot would hold a phone to his ear with his shoulder while flying the aircraft and monitoring computer readouts, in addition to the pilot's intercom system headset, which made this an unnecessarily difficult process.

As if that wasn't challenging and inconvenient enough, the pilot would then have to relay the information to the rest of the aircrew via radio, repeating himself multiple times and delaying mission engagements.

"The Frankenphone really simplifies life in the ground control station," said Capt. Christine, a 432nd Wing pilot.

The Frankenphone solves all those problems by tying the phone line into the pilot's headset intercom system. It essentially puts the aircrew on a party line, mitigating the need to repeat messages numerous times and improving communication clarity.

"This eliminates a lot of the coordination piece by getting everyone on a conference call and getting everybody on the same page, versus via radios and delaying strikes by having to repeat messages to whole aircrew," Marion said.

He went on to say another aspect of coordination the Frankenphone streamlines is the approval process. By allowing key leadership and the aircrew to be on the party line, it provides quality control and the ability to verify the information the JTAC is passing in real time to eliminate miscommunications.

Another great thing about the Frankenphone is that while it improves so many things, it is very low-cost and quick to produce.

Because the Frankenphone is made of recycled materials, it can cost as little as nothing or up to $250 if new parts are used, and it takes less than an hour to make.

"The Frankenphone is allowing us to seamlessly execute the mission, while it saves the Air Force money," said Lt. Col. Gregory, the 432nd Operations Group deputy commander. "A less-than-$250 modification has helped ensure ground forces in combat zones return safely to their families. There's no doubt in my mind that we have saved coalition lives with this device."

To ensure the Frankenphone continues to save lives and the knowledge is not lost after Marion changes duty stations, he has created continuity on how to build the Frankenphone to allow others in his field to continue to evolve the device for future needs.

"I've seen so many good ideas disappear when someone (changes assignments), and this device is still needed by squadrons on Creech {Air Force Base]," Marion said. "Taking that knowledge with me without passing it along would have been wrong."

Published June 2015

Rate this article

View our terms of use and privacy policy